SAP and Fresenius today announced that both companies intend to enter a strategic partnership to accelerate innovation for stronger digital healthcare delivery. Together, the companies plan to create the digital backbone for a sovereign, interoperable, and AI-supported healthcare system. The solutions will combine the expertise of Fresenius, one of the world’s largest healthcare companies, with future-oriented SAP technologies and meet high requirements for data sovereignty, security, and regulatory compliance. The plan is to provide an open, integrated, and data‑driven digital health ecosystem that enables hospitals and medical facilities worldwide to use AI securely and to handle health data responsibly.

Digital sovereignty for healthcare

SAP and Fresenius plan to jointly build an individual, scalable healthcare platform that enables connected, data-driven healthcare processes. Based on this, the companies will develop joint, future-oriented, and AI-supported healthcare solutions to sustainably increase quality, transparency, and efficiency across the entire care chain and set new standards for digital innovation in the healthcare sector. The foundation will be proven SAP technologies and products such as SAP Business Suite, SAP Business Data Cloud (SAP BDC), SAP Business Technology Platform (SAP BTP), and SAP Business AI. These core elements help create a unified, compliant, open, and expandable base for the more-secure exchange and use of data as well as for operating AI models in a controlled environment.

Together, the companies also plan to build a sovereign, European solution for an integrated healthcare ecosystem that supports the integration of modern hospital information systems (HIS) based on SAP’s “AnyEMR” strategy. Interfaces based on open industry standards such as HL7 FHIR will enable the more-seamless connection of HIS, electronic medical records (EMRs), and other medical applications.

“Together with SAP, we can accelerate the digital transformation of the German and European healthcare systems and enable a sovereign European solution that is so important in today’s global landscape. We are making data and AI everyday companions that are secure, simple, and scalable for doctors and hospital teams. This creates more room for what truly matters: caring for patients,” says Michael Sen, CEO of Fresenius.

“With SAP’s leading technology and Fresenius’ deep healthcare expertise, we aim to create a sovereign, interoperable healthcare platform for Fresenius worldwide. Together, we want to set new standards for data sovereignty, security, and innovation in healthcare. Thanks to SAP, Fresenius can harness the full potential of digital and AI-supported processes and sustainably improve patient care,” says Christian Klein, CEO and Member of the Executive Board of SAP SE.

As part of the joint transformation project, both companies plan to invest a mid three-digit million euro amount in the medium term to consistently drive the digital transformation of the German and European healthcare system through the use of digital and AI-supported solutions.

The partnership is implemented through several forms of collaboration. These include joint investments in startups and scaleups, joint technological developments, and close cooperation within coordinated governance structures between the two companies.

This release contains forward-looking statements that are subject to various risks and uncertainties. Future results could differ materially from those described in these forward-looking statements due to certain factors, e.g. changes in business, economic and competitive conditions, regulatory reforms, results of clinical trials, foreign exchange rate fluctuations, uncertainties in litigation or investigative proceedings, the availability of financing and unforeseen impacts of international conflicts. Fresenius does not undertake any responsibility to update the forward-looking statements in this release.

SAP and Fresenius today announced that both companies intend to enter a strategic partnership to accelerate innovation for stronger digital healthcare delivery. Together, the companies plan to create the digital backbone for a sovereign, interoperable, and AI-supported healthcare system. The solutions will combine the expertise of Fresenius, one of the world’s largest healthcare companies, with future-oriented SAP technologies and meet high requirements for data sovereignty, security, and regulatory compliance. The plan is to provide an open, integrated, and data‑driven digital health ecosystem that enables hospitals and medical facilities worldwide to use AI securely and to handle health data responsibly.

Digital sovereignty for healthcare

SAP and Fresenius plan to jointly build an individual, scalable healthcare platform that enables connected, data-driven healthcare processes. Based on this, the companies will develop joint, future-oriented, and AI-supported healthcare solutions to sustainably increase quality, transparency, and efficiency across the entire care chain and set new standards for digital innovation in the healthcare sector. The foundation will be proven SAP technologies and products such as SAP Business Suite, SAP Business Data Cloud (SAP BDC), SAP Business Technology Platform (SAP BTP), and SAP Business AI. These core elements help create a unified, compliant, open, and expandable base for the more-secure exchange and use of data as well as for operating AI models in a controlled environment.

Together, the companies also plan to build a sovereign, European solution for an integrated healthcare ecosystem that supports the integration of modern hospital information systems (HIS) based on SAP’s “AnyEMR” strategy. Interfaces based on open industry standards such as HL7 FHIR will enable the more-seamless connection of HIS, electronic medical records (EMRs), and other medical applications.

“Together with SAP, we can accelerate the digital transformation of the German and European healthcare systems and enable a sovereign European solution that is so important in today’s global landscape. We are making data and AI everyday companions that are secure, simple, and scalable for doctors and hospital teams. This creates more room for what truly matters: caring for patients,” says Michael Sen, CEO of Fresenius.

“With SAP’s leading technology and Fresenius’ deep healthcare expertise, we aim to create a sovereign, interoperable healthcare platform for Fresenius worldwide. Together, we want to set new standards for data sovereignty, security, and innovation in healthcare. Thanks to SAP, Fresenius can harness the full potential of digital and AI-supported processes and sustainably improve patient care,” says Christian Klein, CEO and Member of the Executive Board of SAP SE.

As part of the joint transformation project, both companies plan to invest a mid three-digit million euro amount in the medium term to consistently drive the digital transformation of the German and European healthcare system through the use of digital and AI-supported solutions.

The partnership is implemented through several forms of collaboration. These include joint investments in startups and scaleups, joint technological developments, and close cooperation within coordinated governance structures between the two companies.

This release contains forward-looking statements that are subject to various risks and uncertainties. Future results could differ materially from those described in these forward-looking statements due to certain factors, e.g. changes in business, economic and competitive conditions, regulatory reforms, results of clinical trials, foreign exchange rate fluctuations, uncertainties in litigation or investigative proceedings, the availability of financing and unforeseen impacts of international conflicts. Fresenius does not undertake any responsibility to update the forward-looking statements in this release.

Worldwide

The people behind cancer care

On today’s World Cancer Day, Fresenius highlights what individualized cancer care means in practice. One patient’s story shows why seeing the whole person behind the diagnosis matters across the entire patient journey.

Worldwide

When Art Becomes Measurable

How Quirónsalud explores the impact of images on our well-being and the implications for new approaches in patient care

Worldwide

Comprehensive Care and Compassion: Fresenius' Commitment in Breast Cancer Treatment

Fresenius highlights its commitment to delivering excellent patient care and advancing medical innovation. One patient’s story shows how we bring hope and compassion when it matters most.

Worldwide

Earlier detection, more targeted treatment: Helios sets new standards in diagnosing lung cancer

Doctors are already setting new standards in the early diagnosis of disease with the robot-assisted “Ion endoluminal system” for bronchoscopy.

Worldwide

Antimicrobial resistance is on the rise: How Fresenius responds across all businesses

Antimicrobial resistance (AMR) is a growing global threat. Fresenius is stepping up, through responsible manufacturing, hospital hygiene, and targeted antibiotic use, to help ensure these life-saving medicines remain effective.

Worldwide

On World Prematurity Day:

A little medical miracle at the Helios hospital in Pforzheim

Worldwide

Walking in a Patient’s Shoes

How Fresenius Kabi is using immersive simulations to deepen understanding of chronic illness.

Worldwide

Celebrating 50 Years of Fresubin

This year marks a major milestone in our company’s history: the 50th anniversary of Fresubin®. What began as a clinical solution in 1975 has grown into a trusted and comprehensive enteral nutrition product brand for patients around the world.

Worldwide

More time for patients thanks to AI in the consulting room

With Scribe, our Quirónsalud hospitals are revolutionizing the Spanish healthcare system. The Ai-powered application enhances efficiency and quality while also strengthening the doctor–patient relationship – for more humanity in medicine.

Worldwide

Sustainability at Fresenius: Three questions for Mapi Henríquez de Armas, Director Sustainability at Quirónsalud

"While adapting to climate change is managed at a local level, we have set global emission reduction targets that help us to meet related expectations and to coordinate our efforts."

Germany

First meeting of the year for the Sustainability Advisory Board in Friedberg

Our Sustainability Advisory Board got together for the first meeting of this year at Fresenius Kabi’s production and logistics site in Friedberg.

Worldwide

How Fresenius employees help people with cancer in every phase of the disease

They serve patients beyond expectations and always give their best – not just in the fight against cancer, but also when striving for the highest possible quality of life.

Worldwide

Sustainability at Fresenius: Five questions for Sarah Tix, Head of Group Sustainability

"In our view, sustainability management represents a real opportunity and is essential for securing the resilience, competitiveness, and long-term success of companies."

Germany

“The new ADC medicines represent a real revolution in treatment. This promising therapy can give many patients new hope.”

Professor Dr. Michael Untch from Helios Hospital Berlin-Buch explains how the new antibody-drug conjugates (ADCs) are changing the fight against cancer.

USA

“The flexibility of our Lovo and Cue cell processing systems was the key to success!”

Read our interview with Chris Wegener, to find out more about the device development for CAR-T cell therapy at Fresenius Kabi.

Germany

CAR-T cell therapy: Revolutionary chances of a cure, but costs still too high

How Fresenius Kabi is revolutionizing the treatment of cancer patients with the help of the Lovo and Cue cell processing systems.

Germany

“We combine various innovative solutions to achieve better patient outcomes step by step.”

Helios Hospital Berlin-Buch is one of the first hospitals in Germany to use augmented reality in the operating room.

Europe

Fresenius is a new partner of the Städel Museum

By supporting the renowned museum foundation, the healthcare company demonstrates its social responsibility. The partnership is at the same time a clear commitment to Frankfurt and the Rhine-Main region.

Germany

"Immunotherapies: Boosting Cures and more Patient Wellbeing"

Read our interview to find out what Dr. Anna Ossami Saidy, a doctor in training at the Helios Clinic Berlin-Buch, is currently researching.

Deutschland

Committed to Life: Fresenius now fresher and more modern with new brand identity

#FutureFresenius is making the company fit for the future. And the brand identity must reflect and support this.

Germany

Optimized colorectal cancer screening with AI

How artificial intelligence helps to detect polyps that can’t be seen by the human eye

Germany

CAR T cell therapy: Innovative therapy with the aid of genetically modified cells

“Personalized tumor medicine can be more effective at fighting tumors and produce beneficial therapies with fewer side effects.”

Germany

Welcome to our new podcast format: “Talk Time – CEO Insights with Michael Sen”!

Get to know more about how this year started for Michael Sen, his view on trends like AI in health care and health equity.

Germany

New year, good resolutions: Eating a vegan diet can do a lot for your health and the environment!

Hendrik Otto and Verena Kaiser from Helios explain the benefits of changing your diet

Europe

HOPE gives hope

Quirónsalud focuses on digitalisation to improve oncology patient care

Germany

"This is a tremendous win for the patients"

Interview with Prof. Iwasaki, winner of the Else Kröner Fresenius Prize for Medical Research 2023, endowed with 2.5 million euros.

Germany

Sustainably anesthetized

Anesthetic gas recycling reduces greenhouse gas emissions by 90 percent

Latin America

Planting trees and changing hearts

Fresenius Kabi Employees in the Dominican Republic are working to create a healthier environment.

Europe

‘Sometimes we understand each other without words’

Dr. Veronika Wolter is the first deaf person in Germany to achieve the position of chief physician. She herself uses a hearing prosthesis, and understands her patients very well.

Europe

A robot at the operating table

Fresenius Helios uses the latest robotic technology to make surgery gentler for patients – for example at Helios Hospital Erfurt in Germany.

Europe

Growing up with parenteral nutrition

How two brave adventurers from Switzerland are exploring the world step-by-step.

Europe

From a local pharmacy to a global corporation

As a leading global healthcare group we are dedicated to medicine and human health - values we have upheld since our founding as a pharmacy lab in 1912.

Fresenius has entered into a strategic development agreement with TQ Therapeutics to support the scalable and efficient manufacturing of cell and gene therapies, strengthening its role in advancing next generation treatments.

Under the agreement, operating company Fresenius Kabi receives an exclusive license to integrate TQ Therapeutics’ proprietary cell selection technology into its Cue® Cell Processing System. The combined solution aims to isolate high purity T cells in less than two hours, helping therapy developers streamline processes and accelerate development.

The collaboration is in line with Fresenius’ #FutureFresenius strategy to focus on high value healthcare platforms, strengthen core technologies, and improve patient access through operational excellence and innovation.

By enabling more automated, robust, and scalable cell therapy manufacturing, Fresenius Kabi and TQ Therapeutics aim to support the broader adoption of cell and gene therapies, including applications closer to the point of care.

Fresenius has entered into a strategic development agreement with TQ Therapeutics to support the scalable and efficient manufacturing of cell and gene therapies, strengthening its role in advancing next generation treatments.

Under the agreement, operating company Fresenius Kabi receives an exclusive license to integrate TQ Therapeutics’ proprietary cell selection technology into its Cue® Cell Processing System. The combined solution aims to isolate high purity T cells in less than two hours, helping therapy developers streamline processes and accelerate development.

The collaboration is in line with Fresenius’ #FutureFresenius strategy to focus on high value healthcare platforms, strengthen core technologies, and improve patient access through operational excellence and innovation.

By enabling more automated, robust, and scalable cell therapy manufacturing, Fresenius Kabi and TQ Therapeutics aim to support the broader adoption of cell and gene therapies, including applications closer to the point of care.

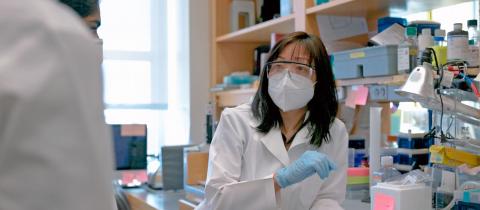

Alma Fredricksen and her partner were about to start a family when she discovered a lump in her breast. After mammography and ultrasound, it was clear that she had breast cancer. On the same day, she found out that she was pregnant – news that made the situation even more emotional. Fredricksen began a course of chemotherapy and discovered that many of the drugs administered were supplied by Fresenius Kabi, the company she worked for. This gave her peace of mind – and filled her with pride.

“Fresenius Kabi products were used throughout my treatment, from the chemotherapy to the birth of my daughter. I have now regained my health and given birth to a healthy child,” says Fredricksen, who was treated in the US. What the patient experienced completely changed her view of her company. “I have first-hand knowledge of how my colleagues work every day to help ensure that patients like me receive comprehensive care and the best possible therapy,” she says.

Terrifying diagnosis: breast cancer. But the chances of being cured are higher than ever

Breast cancer. Words that can stop a person in their tracks and turn their life upside down in an instant. With around 74,500 new cases each year, breast cancer is the most common type of cancer among women in Germany – and around 700 men are also affected.

But the chances of being cured are now higher than ever. Thanks to better screening and modern forms of treatment, mortality rates are continuously falling. “Education delivered by experts is particularly important,” says Prof. Vesna Bjelic-Radisic, Chief Physician in the Breast Center at Helios University Hospital Wuppertal (HUKW). “It is equally essential that women take advantage of the screening services. Studies reveal that more consistent participation in mammography screening programs could prevent a further 20 to 30 percent of deaths. The earlier we detect breast cancer, the greater the chances of a cure.”

Fresenius – a company with a common mission to ensure the best possible care for patients

Fresenius is synonymous with modern medicine and reliable care – worldwide. Whether in hospitals, laboratories, production facilities, outpatient clinics, or administration offices, people everywhere are pursuing the same goal – to improve the lives of patients. This mission ranges from prevention and diagnosis to therapy and aftercare, with the focus always on people – as patients, relatives or employees. That is especially the case for breast cancer treatment, where medical teams and researchers work closely together to ensure the best possible care.

Fresenius Kabi plays an important role along the care journey

Fresenius Kabi plays an important role along the care journey, with Pharma and Nutrition in the focus. This means not only during the therapy itself, but also in the prehabilitation stage – i.e., when preparing for procedures – and in the course of outpatient aftercare.

Fresenius Kabi offers a wide range of oncology medicines, including chemotherapeutic drugs and biosimilars, which are also used in breast cancer treatment.

Adequate and suitable nutrition for patients undergoing oncological treatment is an area of high unmet need and one that Fresenius Kabi can support with specialized products in both parenteral and enteral nutrition, to help improve quality of life outcomes and reduce side effects.

Helios delivers expertise and empathy in breast cancer care provision

Helios has over 50 certified breast centers in Germany, where doctors from across a wide range of disciplines work closely together. Modern imaging techniques, minimally invasive surgery, and systemic and personalized therapy are all standard here, along with aftercare and rehabilitation services. The medical and nursing teams not only guarantee high-quality medical care, but also provide education and offer psychosocial support with a great deal of empathy.

“A cancer diagnosis never affects the body alone,” says Prof. Vesna Bjelic-Radisic “We support our patients through all phases – from their initial diagnosis to their return to life. Rather than just treating the tumor, it’s about seeing the whole person in their life situation.”

Quirónsalud professionals use cutting-edge multidisciplinary procedures

Quirónsalud, the main private hospital operator in Spain and part of the Fresenius Group, also offers breast cancer patients the highest level of care. At its centers, professionals use cutting-edge multidisciplinary procedures: from digital mammography and 3D tomosynthesis to intraoperative radiotherapy and personalized hormonal and chemotherapy treatments.

Special emphasis is always placed on individualized therapy: interdisciplinary teams adapt each treatment to the type of biological tumor and the patient’s circumstances. “Compared to recent years, we are witnessing a revolution in the early diagnosis and treatment of these tumors. In both early and advanced disease, the majority of patients are cured, and the most chronic patients have an excellent life prognosis,” explains Dr. Lucía Gonzalez Cortijo, head of the Medical Oncology Service at Quirónsalud Madrid University Hospital.

Fresenius is also actively involved in research

Fresenius is also actively involved in research. One model institution is Helios University Hospital Wuppertal, whose breast center under the direction of Prof. Vesna Bjelic-Radisic was named “Germany’s best study center” by the German Breast Group. Patients are given access to innovative therapies here – often long before they are generally available.

Another hotbed of research can be found at Helios Hospital Berlin-Buch, where Prof. Michael Untch has been researching antibody-drug conjugates (ADCs) for over 20 years. These combine targeted antibodies with cell-killing agents and offer new hope, particularly for patients who have exhausted all other treatment options. In a long-term study, around 90 percent of women who received such medicine survived – even though they previously had a very poor prognosis.

Quirónsalud is also involved in international studies on new diagnostic and treatment approaches – focusing on the combination of targeted therapies and immunotherapies, for example. Its centers in Madrid, Barcelona, and Seville are conducting various Phase II and III studies in conjunction with the Spanish Society of Medical Oncology (SEOM), Spanish universities, and other European partners. Fresenius employees are committed to rising to all these challenges with the aim of enabling patients to make a return to leading a normal, healthy life.

Just like Alma Fredricksen: Following her successful treatment, she has returned to work and resumed her former life. And is grateful to be part of it all again. “Behind every order, every project, and every decision are people who we can help in a very specific way,” says Fredricksen.

Further information

Further information and the latest articles on the subject of breast cancer can be found on the Helios website: www.helios-gesundheit.de/brustkrebs

February 25, 2026 - 01:30 pm

Bad Homburg, Germany

Conference Call Full Year Results 2025

Financial Highlights FY/2025

Group Revenue 1

€ 22554 m

+7% 2

FY/24: €21,526 m

Group EBIT 1

€ 2595 m

+6% 3

FY/24: €2,489 m

Net income 1, 4

€ 1619 m

+12% 3

FY/24: €1,461 m

EPS 1, 4

€ 2.87

+12% 3

FY/24: €2.59

KABI Revenue 1

€ 8612 m

+7% 2

FY/24: €8,414 m

HELIOS Revenue 1

€ 13550 m

+7% 2

FY/24: €12,739 m

1 Before special items

2 Organic growth rate adjusted for accounting effects related to Argentina hyperinflation

3 Growth rate at constant currency (cc) and adjusted for Argentina hyperinflation

4 Excluding Fresenius Medical Care

Biopharma – Meet the Management

Visit our capital markets event page for detailed information and the replay of the webcast.

Letter to our shareholders

2024 was a dynamic and successful year for Fresenius. More than 176,000 colleagues have made Fresenius more innovative, more focused, and more efficient. This is an outstanding team effort, and millions of patients worldwide benefit from it.

Sustainability Statement

As a healthcare Group, we make a significant contribution to providing people with access to healthcare and producing the necessary medical technology and pharmaceuticals.

Fresenius Kabi Story

Throughout 2024, Fresenius Kabi has significantly strengthened its role as a leading provider of healthcare products and therapies for critically and chronically ill patients: by investing in key growth areas and making a difference in patients’ lives.

Fresenius Helios Story

Innovation in hospitals is key! Fresenius Helios is Europe’s leading private network of hospitals and outpatient clinics and is continuously expanding its role. Discover how they’re driving medical excellence and advancing digital solutions.

Library

January 19, 2026

Frankfurt, Germany

UniCredit Kepler Cheuvreux 25th German Corporate Conference

January 19 – 20, 2026

Dividend policy reflects capital allocation priorities: As part of the full year reporting in February 2025, Fresenius defined a new dividend policy designed to ensure attractive shareholder returns while maintaining strategic flexibility. Going forward, Fresenius will pay out 30 to 40% of its Group core net income excluding Fresenius Medical Care and before special items as dividend.

Dividend 2025

Fresenius remains fully commitment to delivering attractive shareholder returns. For fiscal year 2025, the Company will propose a dividend of €1.05 per share. This corresponds to a payout ratio of 37%, at the upper half of the 30 to 40% range of core net income1,2, as specified in the Fresenius Financial Framework.

1 Before special items

2 Excluding Fresenius Medical Care

Contact

Vice President Investor Relations

Deputy Head of Investor Relations

T: +49 (0) 6172 608-5167

florian.feick@fresenius.com

February 25, 2026 - 01:30 pm

Bad Homburg, Germany