Top government and company officials joined local executives and employees as Fresenius Kabi inaugurated yesterday the major expansion of the company’s production site in the Dominican Republic.

In Haina, just outside the Dominican Republic’s capital and biggest city, Santo Domingo, the company manufactures apheresis sets. These products are used, for example, to collect blood components such as platelets or plasma. Fresenius Kabi undertook the expansion to meet the rising demand for these high-quality disposables used for critically important donations.

President Danilo Medina of the Dominican Republic was an honored guest at the ceremony. Also in attendance were Mats Henriksson, CEO of Fresenius Kabi, and Dr. Christian Hauer, President Transfusion Medicine and Cell Therapies Division of Fresenius Kabi.

Mats Henriksson highlighted that Fresenius Kabi is one of the leading international companies supplying transfusion medicines and cell therapies to blood services and hospitals. “We are proud to continue and further develop our decades-long presence in this region, and we are very excited about this expanded facility,” Henriksson said. “This is yet another step in improving the lives of chronically and critically ill people around the world. We all look forward to putting ever more leading-edge disposables and devices in the hands of the people who are caring for patients and collecting life-saving plasma donations.”

Christian Hauer said the plant expansion will strengthen the company’s role as a major global exporter of apheresis and plasma collection sets. “Broadening our production activities in the Dominican Republic will increase our ability to produce and supply essential products for patients around the globe,” Hauer said.

Fresenius Kabi’s first plant building at the Haina site, which opened in 1987, covers around 18,000 square meters (195,000 square feet). The expansion, in which Fresenius Kabi is investing more than €30 million, doubles the size of the site’s newer, second plant building to around 15,000 square meters (160,000 square feet). The new space houses advanced production equipment, plasma kit assembly lines and sterilization units that double the cleanroom and storage capacity. The site also includes a large warehouse.

A global healthcare company specializing in life-saving medicines and technologies for infusion, transfusion and clinical nutrition, Fresenius Kabi has almost 40,000 employees worldwide, including more than 3,500 in Haina. The life-saving disposables for transfusion medicine and cell technologies manufactured in Haina are exported to global markets to make a difference in the quality of life of patients worldwide.

This release contains forward-looking statements that are subject to various risks and uncertainties. Future results could differ materially from those described in these forward-looking statements due to certain factors, e.g. changes in business, economic and competitive conditions, regulatory reforms, results of clinical trials, foreign exchange rate fluctuations, uncertainties in litigation or investigative proceedings, and the availability of financing. Fresenius Kabi does not undertake any responsibility to update the forward-looking statements in this release.

After four years of construction Fresenius Vamed has completed the new main building at University Hospital Schleswig-Holstein (UKSH) in Lübeck. Following the opening in August of the new main building at the UKSH’s other location, in Kiel, the modernization of Germany’s second-largest university hospital is now largely complete. In addition to the new construction and the comprehensive renovation of the two university hospital locations, the project includes their technical management through 2044. With a total volume of €1.7 billion, the UKSH modernization is currently the biggest public-private partnership project in Europe’s healthcare sector.

VAMED Vitality World has been named the “World’s Best Thermal Spa & Medical Wellness Operator 2019” at the World Spa Awards. Four VAMED Vitality World facilities – Geinberg5 Private Spa Villas, St. Martins Therme & Lodge, Therme Laa Hotel & Spa and la pura women’s health resort – also won in their individual categories. VAMED Vitality World, part of Fresenius Vamed, operates a total of nine spa and health resorts in Austria.

Fresenius Medical Care North America (FMCNA) has launched its new connected health platform called TheHub. The platform is comprised of three integrated applications - PatientHub, CareTeamHub and ProviderHub - that enable patients, care teams, and providers to better collaborate and monitor patient treatments. Research by FMCNA indicates that patients who actively use these connected health solutions have a 20 percent lower risk of hospitalization, higher transplantation rates, and stay on the modality longer.

Fresenius Kabi has completed the expansion of its plant in Aquiraz, Brazil, increasing the facility’s capacity for parenteral nutrition production by around 30 percent. The company expects to hire about 50 new employees to bring the plant’s workforce to about 850. Fresenius Kabi, which has been active in Brazil for more than 40 years, invested some €20 million in the expansion and modernization of the Aquiraz plant.

The healthcare group Fresenius has nearly completed the work begun two years ago to expand company headquarters in Bad Homburg. Two new office buildings; “EK3” at Else-Kröner Street and “D15A” located at Daimler Street have been in operation since April. Now the redesigned exterior grounds fronting Else-Kröner Street are completed. These grounds link the additions with existing buildings to create the new “Fresenius Campus.”

To mark the occasion, the company leadership yesterday invited employees who work on the premise to a “Campus Fest.” Together with Bad Homburg Lord Mayor Alexander Hetjes and Fresenius Chief Executive Officer Stephan Sturm, they celebrated this new milestone in Fresenius company history.

In opening remarks, Stephan Sturm emphasized the ongoing growth at Fresenius, both worldwide and in the spa city. “Only 10 years ago we had about 2,000 employees in Bad Homburg. Now we have twice as many. All the signs point to continued growth in the future – because demand for our products and services is growing worldwide, and because our employees are doing everything they can to meet this demand.”

“The company’s headquarters also symbolizes the impressive growth of Fresenius, which continues to make its mark on Bad Homburg as a business location,” said Hetjes. “The energy efficiency is exemplary, and thanks to the headquarters’ campus character and modern design the company can offer employees a very attractive working environment in our city.”

Construction on EK3 began in September, 2017. The five-story building accommodates 600 modern office workspaces, conference rooms, an additional employee cafeteria and an underground parking garage. Work on D15A began in May, 2018. This building expands on the existing Research & Development Center of Fresenius Medical Care, to which it is connected by a footbridge. It offers 150 office workspaces spread over six floors.

Altogether Fresenius invested 70 million euros in the headquarters expansion. The company currently employs about 4,000 people in Bad Homburg and another 300 in neighboring Oberursel.

Construction on another office building to be rented by Fresenius, Uniqus 2 at Horex Street, is expected to be finished by the end of this year. The building will accommodate 250 workspaces.

Fresenius Kabi has opened a new research and development center for biosimilars in Eysins, in the Swiss canton of Vaud. The facility, in which the company invested about €15 million, will strengthen Fresenius Kabi’s capability to develop new biosimilars, particularly in the areas of autoimmune diseases and oncology. A biosimilar is a drug that is “similar” to another, already approved biologic drug. More than 100 employees representing over 20 nationalities work at the Eysins site, and the company plans to expand the workforce in the near future.

After four years of construction Fresenius Vamed has completed the new main building at University Hospital Schleswig-Holstein (UKSH) in Kiel. The completion marks the first milestone in the modernization of Germany’s second-largest university hospital, with the main building of the Lübeck location scheduled to open in November. The project includes new construction and the comprehensive renovation of the two university hospital locations, some 80 kilometers (50 miles) apart in Schleswig-Holstein state, and their technical management through 2044. With a total volume of €1.7 billion, the UKSH’s modernization is currently the biggest public-private partnership project in Europe’s healthcare sector.

Fresenius Helios has opened a new Helios Prevention Center in Berlin, as the company continues the expansion of its occupational medicine activities into a standalone business area. The modern, 440-square-meter (4,700-square-foot) center in the heart of Germany’s capital offers comprehensive check-ups from a single source. HCP patients are accompanied throughout the check-up by their own personal physician, and do not have to search for the right department for their next test, deal with different contact persons, or face long waiting times. And if a test turns up something requiring medical treatment, the patient has direct access to the Helios healthcare network and an exclusive hotline for making appointments with specialists.

Fresenius Medical Care, the world’s largest provider of dialysis services and products, celebrated today the 40th anniversary of the company’s Schweinfurt, Germany plant. Joining employees and their family members for the festivities were numerous business and political representatives, including Schweinfurt Mayor Sebastian Remelé.

Schweinfurt is Fresenius Medical Care’s largest development and manufacturing facility for dialysis machines and other medical technology devices. Over the past four decades more than 800,000 dialysis machines have been made at the site, where the company is now investing some €20 million in a new, 8,000-square-meter (86,000-square-foot) technology center. The Schweinfurt facility’s workforce now numbers more than 1,200, with about a third of the employees involved in research and development.

“Schweinfurt is a huge success story – not just for Fresenius Medical Care, but even more so for our patients around the world,” said Rice Powell, CEO of Fresenius Medical Care. “For 40 years now, we have been developing life-sustaining products here at the very highest level, and we’re doing our best to continue writing new chapters in that success story. With the building of the new technology center, we are working to mesh development and production at this site even closer together, so that we can provide even better dialysis machines for our patients in the future.”

“I am very proud that Fresenius Medical Care is established in Schweinfurt and from here developed into the world market leader for dialysis machines,” said Mayor Remelé. “These dialysis systems are used to treat several hundred thousand patients with chronic kidney failure. In the name of the city of Schweinfurt, and personally, I want to wish Fresenius Medical Care continued great success in this important field.”

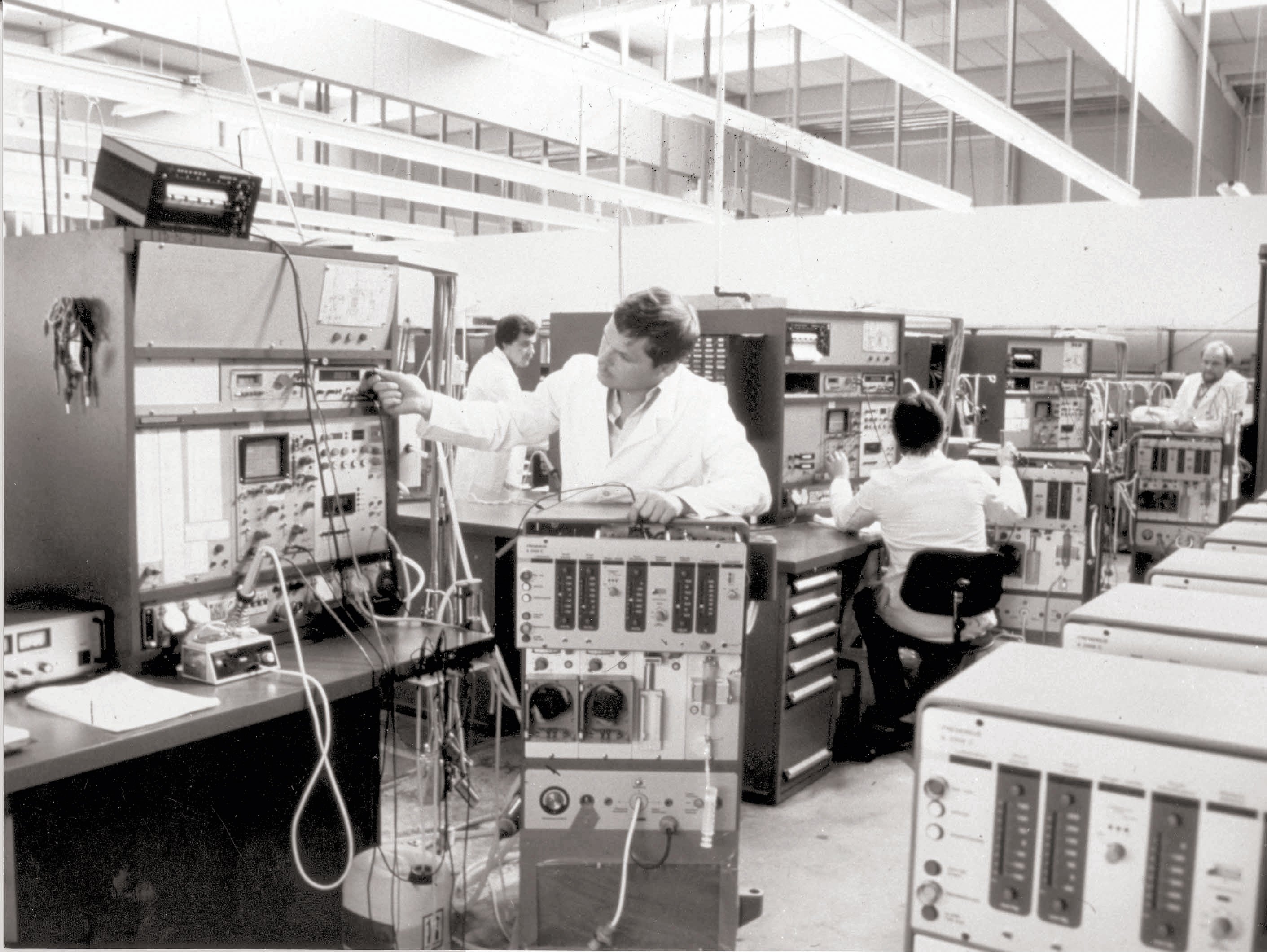

The plant’s history dates back to 1979 and the acquisition of a vacant factory building in a Schweinfurt industrial zone. There, under the business name MTS Medizin-Technische Systeme Schweinfurt GmbH, 40 employees began producing the first dialysis machine developed by Fresenius – the A2008C, which won the gold medal for technical innovation at the Leipzig Trade Fair that same year. By 1984, every second dialysis machine produced in Germany was “Made in Schweinfurt.” The A2008C would go on to become the world’s leading and best-selling dialysis machine, a position Fresenius Medical Care still holds following the introduction of the A2008C’s successor models. Today, more than half of all dialysis machines sold worldwide are made by Fresenius Medical Care.

Dialysis machines, bloodline systems and dialyzers – the latter often dubbed “artificial kidneys” because this is where the blood is cleaned – are the most important products for treating chronic kidney disease. During treatment, the dialysis machine pumps the patient’s blood through bloodlines, monitors its circulation through the dialyzer, and adds anti-coagulants. Treatments are generally carried out three times weekly, taking between three and six hours each.

This release contains forward-looking statements that are subject to various risks and uncertainties. Actual results could differ materially from those described in these forward-looking statements due to certain factors, including changes in business, economic and competitive conditions, regulatory reforms, foreign exchange rate fluctuations, uncertainties in litigation or investigative proceedings, and the availability of financing. These and other risks and uncertainties are detailed in Fresenius Medical Care AG & Co. KGaA's reports filed with the U.S. Securities and Exchange Commission. Fresenius Medical Care AG & Co. KGaA does not undertake any responsibility to update the forward-looking statements in this release.

Pagination

- Previous page

- Page 3

- Next page